REBS Zentralschmiertechnik GmbH was founded in 1948 and has developed into a modern, international company.

The family-run company, now in its 3rd generation of management, employs over 150 staff worldwide and is the leading provider in many areas of central lubrication technology.

Company founder Alexander REBS already earned an excellent reputation with the invention of the progressive distributor. Oriented to the needs of its customers, REBS is constantly growing with its subsidiaries REBS TURBOLUB GmbH, REBS Lubrication Technology Ltd., Shanghai and REBS Lubrication India Pvt. Ltd., Mumbai.

For more details on company’s products and history please visit www.rebs.de

Quick and hot – not a problem for us!

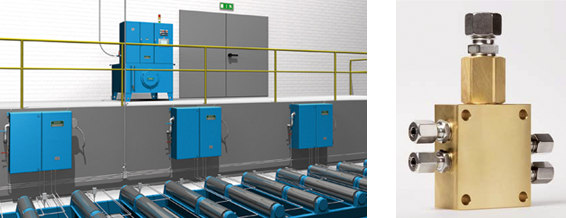

High temperatures, high speeds and loads – the REBS oil-air lubrication with TURBOLUB® distributors is designed for use in extreme manufacturing processes, as well as with small systems from 2.5 liters.

The wear-resistance of the distributors and the low lubricant consumption also make these systems economically attractive.

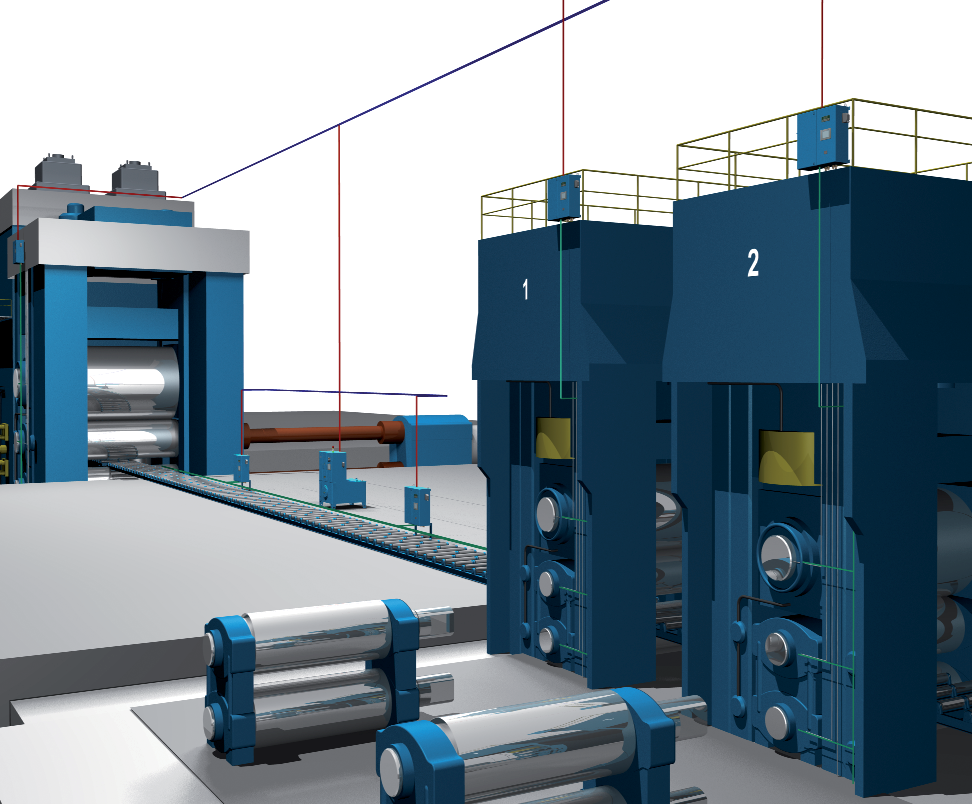

The patented TURBOLUB® oil-air lubrication system is the optimal solution for efficient and reliable lubrication of bearings. Our technology is used for example in continuous casting plants, wire rolling mills and profile iron rolling mills, in cold and hot rolling mills, as well as in roller beds and tunnel kilns.

We always have the right system for individual requirements. System parts which are located a great distance from each other are supplied with a lubrication system by a satellite version of the TURBOLUB® system. It can easily be retrofitted with other SAT stations if the lubrication system needs to be expanded.

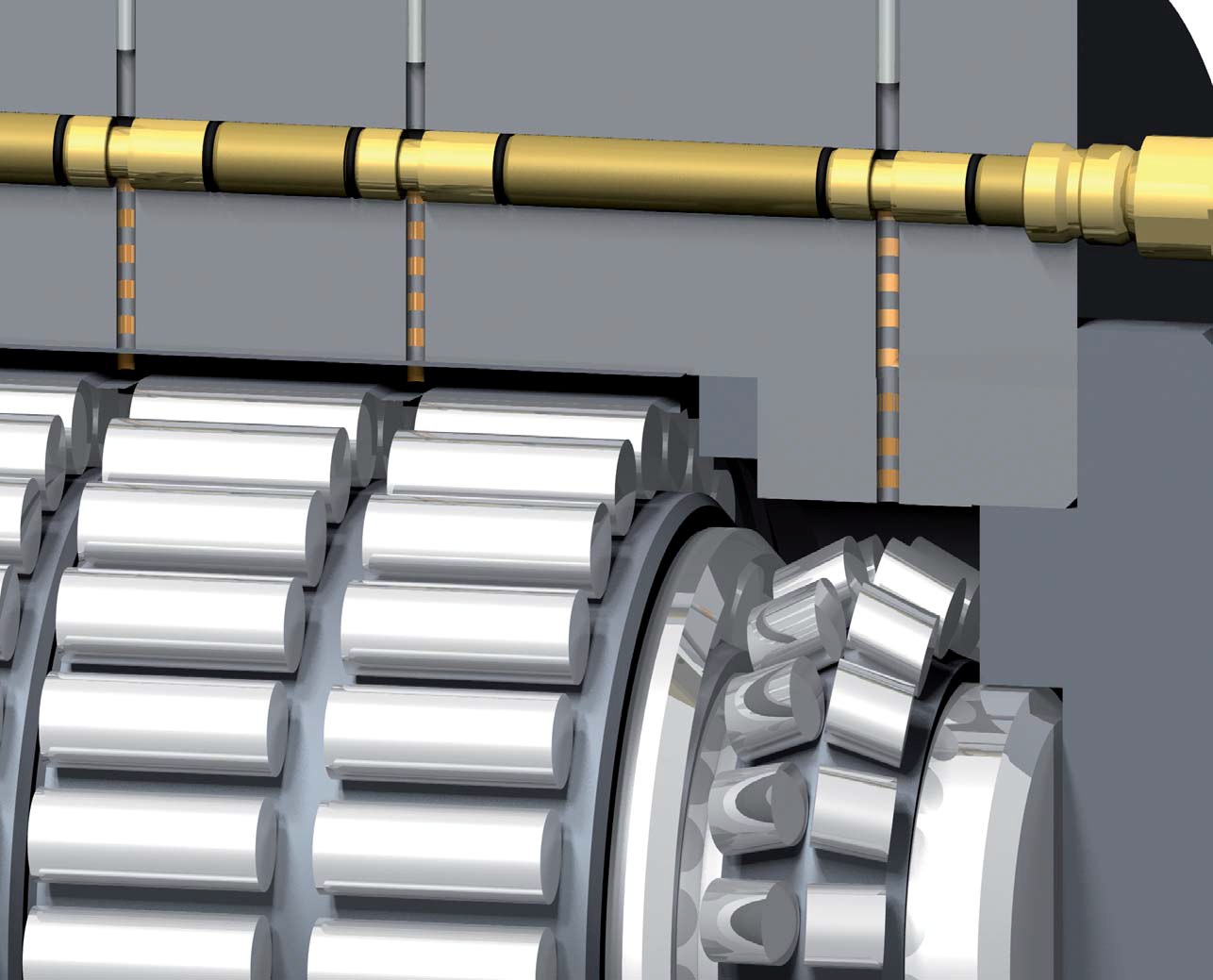

Functional principle

The oil pressure tank is the heart of every system. Here the oil is prepared for further use. A pump conveys the oil directly or via a progressive distributor to a mixing block, which distributes oil and compressed air to the oil-air lines. In these lines under the influence of the compressed air, a continuous oil film is gradually formed from the impulse-fed oil. This film moves in streaks along the inner line of the oil-air line to the bearing point, wear point or seal. The penetration of foreign matter (scale, water, emulsion, etc.) is prevented by the arising overpressure in the rolling bearing.

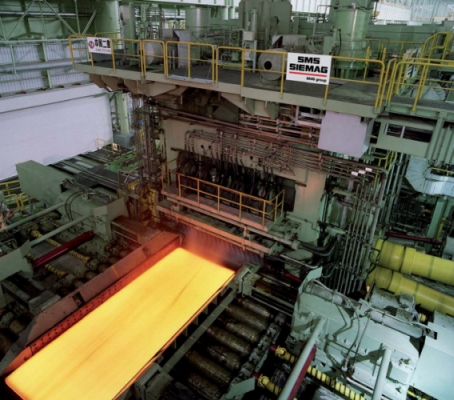

Applications in steel industry

- Continuous casting machines lubrication (billet, bloom and slab casters)

- Discharge roller tables lubrication for billet, bloom and slab casters

- Hot rolling mills for long products (rebar % wire rod mills)

- Hot sections rolling mills (rail and heavy & medium section rolling mills)

- Hot strip mills

- Cold strip mills

- Chain links for hot deep galvanizing lines

- Transfer car rolling elements continuous lubrication

Some examples for REBS TURBOLUB applications in continuous casting plants.

Some examples for REBS TURBOLUB applications in continuous casting plants.

Rolling mill bearing lubrication with REBS TURBOLUB Oil-Air Mix

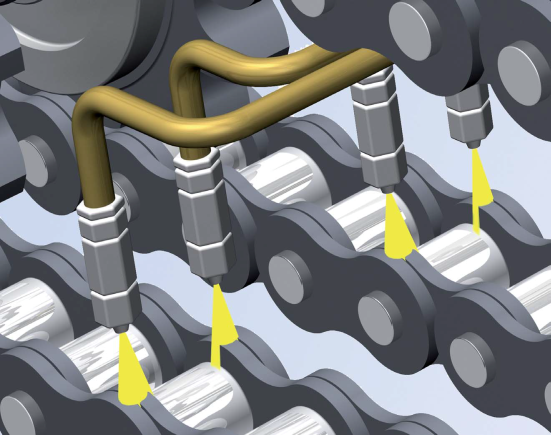

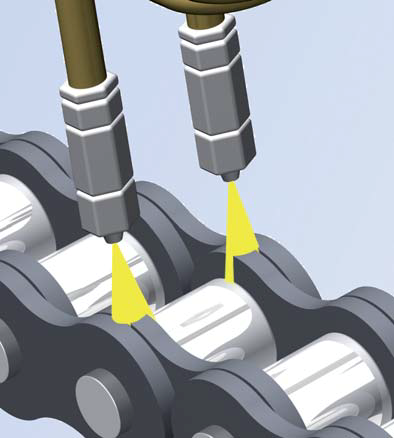

Examples of chain lubrication with REBS TURBOLUB in hot deep galvanizing lines, both with brush and spraying techniques.

REBS TURBOLUB oil air lubrication systems can be used also in aluminum mills and railways as well.

Advantages of REBS TURBOLUB® technology

- Doubling of bearing and segment service life

- Low bearing temperatures

- Overpressure protects the bearing from dust, scale and water

- Precisely metered lubricant quantities, thus no additional heat through over lubrication

- Consumption of only approx. 5t oil to 100t grease

- No environmental pollution

- Low maintenance costs

- Environment protection through metered oil-air quantities