M-TEC WIRE – HIGH PERFORMANCE Ca WIRE , NEW TECHNOLOGY,EXCELLENT PERFORMANCE, LOWEST Ca INJECTION COST

M-tec wire GmbH is a part of the group m-tec. The group, with head-office in Töging am Inn and production facilities in Voerde, Germany, is specialised in additives for the steel mills and foundries and cored wires. m-tec wire is the business unit specialised in cored wires. We provide a complete range of injection core wires to the global steel industry and foundries: CaSi, CaFe, FeNb, FeTi, FeB, S, C…

Our focus is on high performance cored wires for Calcium treatment:

- Max-Cal®: welded thick sheath pure Calcium cored wire produced with extruded Calcium rod

Calcium Treatment

Sufficient quantity of Calcium has to be added, with good calcium distribution in the melt, to avoid that high-melting-point calcium aluminate inclusions remain in the steel. If this is not the case, the aluminate inclusions remain solid at steel making temperatures and may affect casting and rolling performance as well as the steel properties. The Calcium shall be added progressively to reach a ratio 12 CaO-7 Al2O3 to modify the solid inclusions into liquid state with lower melting point (ca. 1400 °C).

M-TEC WIRE will provide sufficient technical support and optimize your Ca injection practices with well experienced technical support team.

Types of inclusions

| Calcium-Aluminate C = CaO and A = Al2O3 |

Composition | Elemental Ca : Al ratio |

Estimated melting point |

| C2A (not common) | 2CaO-Al2O3 | 1 : 1 (1.0) | 1400°C |

| C12A7 (desired) | 12CaO-7Al2O3 | 12 : 14 (0.85) | 1400°C |

| CA (undesired) | CaO-Al2O3 | 1 : 2 (0.50) | 1600°C |

| CA2 (undesired) | CaO-2Al2O3 | 1 : 4 ( 0.25) | 1760°C |

| CA6 (undesired) | CaO-6Al2O3 | 1 : 12 ( 0.08) | 1830°C |

Max-Cal®

M-TEC WIRE focused on to improve Ca injection practice and create a cost saving with new generation pure extruded Ca wire with welded sheath Max-Cal®

Calcium is a chemical element with symbol Ca and atomic number 20. It is a soft gray Group 2 alkaline earth metal, fifth-most-abundant element by mass in the Earth’s crust.

| Dencity (Room Temp.) |

Dencity (Melting Point) |

Melting Temperature | Boiling Point |

| 1,55 g/cm3 | 1,378 g/cm3 | 842 0C | 1484 0C |

Three main design factors determine the high metallurgical performance of Calcium cored wires:

- Thick sheath: it allows injecting the wire deep into the ladle, below the level with sufficient ferrostatic pressure to keep the Calcium liquid at steel making temperatures. All wires with thick sheath (0.6 mm+) have a significantly better performance than conventional (CaFe/CaSi/Ca) wire with wall thickness 0.4 mm.

- Use of solid Ca rod. Ceteris paribus, cored wires made with solid Ca rod have superior performance than wires made with powders. The thermodynamics of the melting process of the Ca in powder form and as rod are different: the contact surface per unit of Ca in powder being superior, the melting is faster.

- Use of welded sheath: the Calcium is hermetically encapsulated in the wire. Contrary to wires with folded sheath, welded wires do not open before reaching the depth with sufficient ferrostatic pressure. The Ca losses due to evaporation are therefore more limited, more Ca is available to react with the inclusions.

The welded sheath is the key factor for good metallurgical performance!

Max-Cal® is the only Ca-cored wire currently available on the market combining these 3 features to produce exceptional metallurgical performance.

- Typically, with other Ca-containing cored wires, 60 to 180 g of Calcium per ton of steel are added to achieve the required metallurgical performance: effective inclusions modification and no clogging.

- Max-Cal®reduces the injected Ca quantity from at least 2 to 4 times for equivalent metallurgical results (Ca performance factor 2 to 4).

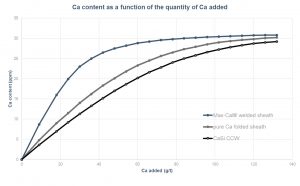

- The Ca-increase curves are much steeper than the ones of other Ca-containing wires (see the graph below).

- Metallurgically, Max-Cal®is the best performer in terms injected Calcium quantity and Calcium yield.

- Economically, Max-Cal®achieves the lowest Ca-treatment cost per ton.

Max-Cal® Maximal Effectiveness :Main Advantages

- Max-Cal® has a significantly better metallurgical performance against:

- conventional CaSi/CaFe wires: from 2 to 3 times (7.3 to 10 times mess filler!);

- pure Calcium cored wires with folded sheath and extruded Ca: 5 to 2.5 times;

- pure Calcium cored wires with folded sheath and powdered Ca: 3 to 4 times.

- Better Metallurgical Performance; The injected quantity of Calcium is significantly reduced (in the proportions above) while producing similar or better metallurgical performance.

- Cost Reduction; Because of the Max-Cal® excellent metallurgical performance and the reduction of the added Calcium quantities, cost reductions between 6% and 10% are achieved.

- Lower Splashing; Release of calcium deep into the ladle means lower splashing and eventually allows a better utilisation of ladle capacity as the freeboard can be reduced.

- Reduction of fuming: -50% to -70% in some cases, as the reaction is more quiet => lower impact on environment and savings on filtering.

- Maintenance costs can be reduced as a consequence of less refractory and equipment damage caused by splashing.

- No Modification for Wire Feeder; Max-Cal® can be fed by existing feeding equipment without modifications.

Max-Cal® Maximal Effectiveness: Additional Advantages

- Better Calcium distribution in the ladle.

- Better inclusions modification: concentration of the aluminate inclusions in the zone of the liquid state on the ternary diagrams.

- Lower or eliminated risk of clogging.

- Much better stability of the Ca results, tighter Ca ppm normal (Gauss) distribution.

- Reduction of coil handling (2-4 times), as much less Ca injected.

- Reduction of storage surface needed for the coils.

- No wire breakages: mechanical stability guaranteed by the welded sheath and the solid extruded Ca rod inside, unlike wires made with powder (guaranteed by the sheath only).

- If several types of wire used for Ca-handling, possible use of only one wire type.

- If properly stored, practically unlimited shelf-life: the Ca inside is hermetically encapsulated.

- Reduced stiffness compared to other wires with a thick sheath, as it is annealed. The stiffness of Max-Cal® is comparable to, or slightly higher than the stiffness of conventional cored wires in 13 mm diameter and 0.4 mm thick wall

Max-Cal® Maximal Effectiveness: Comparision Chart

REFERENCES;

| Company | Country |

| Acciaerie Venete Padova | Italy |

| Acciaerie Venete Sarezzo | Italy |

| Alfa Accaiai | Italy |

| ArcelorMittal Differdange | Luxembourg |

| ArcelorMittal Fos | France |

| ArcelorMittal Ruhrort | Germany |

| ArcelorMittal Warsaw | Poland |

| Arvedi | Italy |

| Ascometal Fos | France |

| Ascometal Hagondange | France |

| Benteler | Germany |

| Dillingerhütte | Germany |

| ESF Feralpi | Germany |

| Georgsmarienhütte | Germany |

| HKM | Germany |

| Italfond | Italy |

| Lucchini | Italy |

| Nunki Steel | Italy |

| Ovako Hofors | Sweden |

| RIVA BES Brandenburger Elekrostahlwerke | Germany |

| RIVA HES Henigsdorfer Elekrostahlwerke | Germany |

| RIVA Caronno | Italy |

| RIVA Lesegno | Italy |

| Saarstahl | Germany |

| Salzgitter AG | Germany |

| Severstal | Russia |

| Stomana | Bulgaria |

| Schmiedwerke Gröditz | Germany |

| Tata Steel | Netherlands |

| Tenaris Dalmine | Italy |

| ThyssenKrupp Steel | Germany |

| Trinecke Zelezarny | Czech Republic |

| Vitkovice Heavy Machinery | Czech Republic |

| ÇOLAKOĞLU METALURJİ (Deneme Çalışması) | Türkiye |

| KROMAN ÇELİK (Deneme Çalışması) | Türkiye |

| ÇEMTAŞ (Deneme Çalışması) | Türkiye |